The Structure of a Reciprocating Compressor

The Working Principle of a Reciprocating Compressor

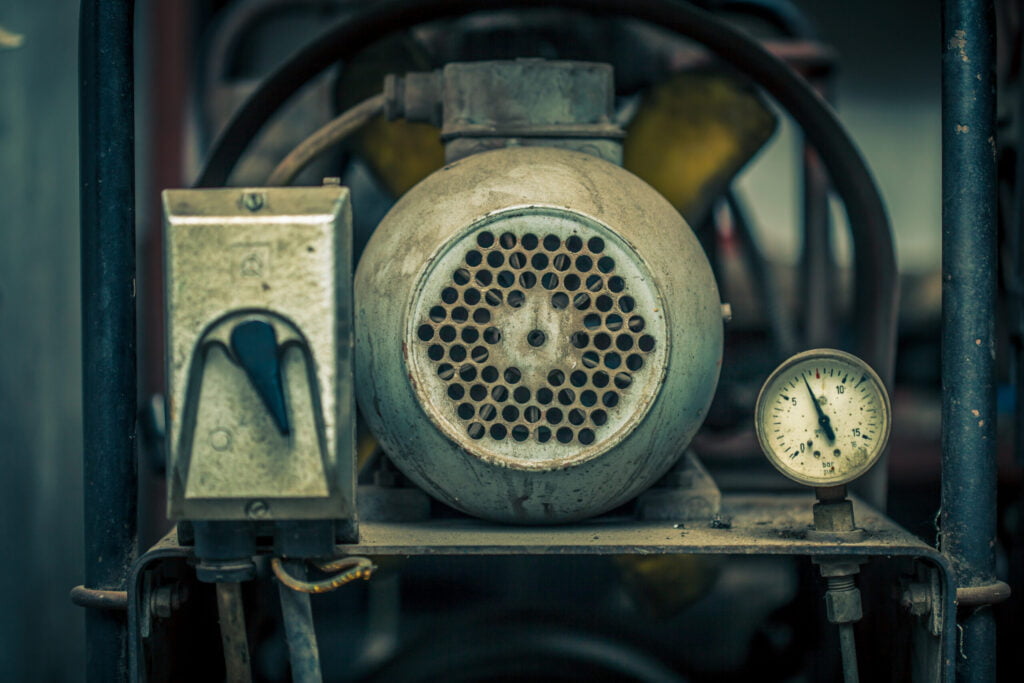

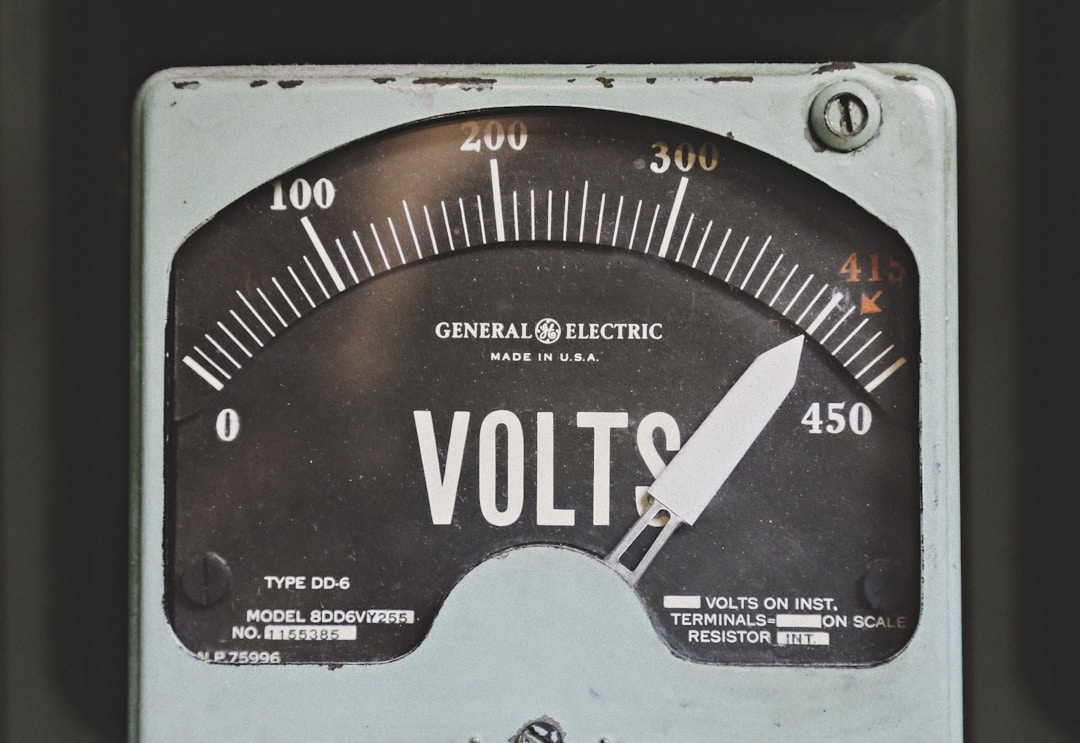

The working process of a compressor starts with sucking in gas from the outside environment, which enters the system through a suction valve. When the piston moves downward, the pressure inside the cylinder decreases. This shift encourages the gas to enter the cylinder, filling up the void created by the movement of the piston. When the cylinder fills with the gas, the compression process starts. The piston then starts moving upward, consequently increasing the pressure within the cylinder. Compressing the gas increases its temperature, which can be dangerous, leading to possible explosions in some cases. This is why manufacturers often incorporate cooling systems in these compressors to keep temperatures under control. When the gas is adequately compressed, it’s time to discharge it from the cylinder through an outlet valve. As the piston reaches the peak, the high pressure causes the outlet valve to open releasing the compressed gas into the output system. The compressor continues to follow this routine process of intake, compression, and discharge to perform its function.The Energy Efficiency of Compressors

Learning To Troubleshoot Common Issues

Working with compressors should present minimal challenges, given the proper understanding. Considering the intricate machinery involved, pay attention to detail to identify potential issues promptly. Fault detection in the initial stages saves you from potential massive breakdowns. Compressors often produce abnormal noises when mishaps are looming. When you hear unwarranted sounds emanating from your compressor, take a moment, don’t panic. Then, meticulously inspect the piston and cylinder for wear or damage, which often are the prime culprits. Erratic temperature fluctuations serve as another red flag. A sudden spike in heat, specifically in the compressor’s head or outlet pipes, means immediate attention is necessary. There’s a likelihood of overloads or inadequate cooling, and your prompt intervention can prevent any further deterioration. Finally, oil leaks not only result in decreased efficiency but also pose environmental risks. See a leak? Don’t turn a blind eye. Swiftly strategize on containment, then source for the leak’s origin.Sustainability Practices in Operating High-Speed Compressors

Operating compressors with an eye on sustainability could prove hugely beneficial. You not only create a balance in the ecosystem but also extend the lifespan of your compressors. This eco-conscious route combines both operational efficiency and responsibility toward the environment. Efforts toward energy-conserving practices should be your maiden exercise. By maintaining proper suction pressure, you reduce energy losses and enhance system efficiency. Routine maintenance checks are integral to this strategy, ensuring the compressor operates at optimal conditions. Water conservation is another critical area to observe. Where feasible, substitute water-based cooling systems for air-cooled ones, minimizing water usage when cooling these compressors. Your venture into a water-efficient operation has the potential to massively undercut wastage. Waste management, particularly for used compressor oil, presents a tremendous challenge. Essential steps to explore are refining the used oil for reuse or safe disposal of it. Remember, sustainable practices in operating high-speed compressors assure not only the longevity of your machinery but also a cleaner, safer workspace.Why Your Business Needs Compressors

pressure, reciprocating compressor, compressor, pump, cylinder, valve, compressed air, machine, oil, engine, refrigerant, energy, lubricant, volume, crankshaft, piston rod, heat exchanger, warranty, suction, vibration, united arab emirates, stroke, belt, natural gas, screw, reciprocating motion, motion, efficiency, trinidad and tobago, liquid, construction, czech republic, republic, crosshead, compression ratio, wear, horsepower, brunei, algeria, noise, connecting rod, tunisia, slovakia, zambia, manufacturing, saint vincent and the grenadines, centrifugal compressor, tank, mozambique, antigua and barbuda, innovation, ethiopia, intercooler, latvia, technology, papua new guinea, djibouti, bosnia and herzegovina, dominica, lithuania, pipeline, botswana, namibia, zimbabwe, libya, uganda, south america, grenada, north america, malawi, hungary, arabs, intake, belarus, slovenia, oil pump, sierra leone, benin, korea, tobago, lesotho, paraguay, rotation, somalia, fluid, wear and tear, togo, inspection, diaphragm, tajikistan, distributor, suriname, duty cycle, agriculture, mauritania, crankcase, kyrgyzstan, liberia, bhutan, heat pump, cast iron, cylinder head, downtime, burundi, mali, burkina faso, rwanda, sustainability, barbuda, laos, ammonia, extended warranty, recip compressor, reciprocating piston compressor, 2v41c60vc quincy, recip air compressor, air compressor, hydrogen, diaphragm compressor, poppet valve, air conditioning, captcha, privacy policy, vacuum, scroll compressor, turbine, nitrogen, vehicle, relief valve, flywheel, reciprocating air compressor, reciprocating compressor working principle, diesel engine, cost, contamination, high pressure, condition monitoring, principle, airflow, radiator, pipe, transmission, friction, renewable energy, automation, storage tank, thermodynamics, carbon, filtration, analytics